| Berndt Wischnewski | Richard-Wagner-Str. 49 | 10585 Berlin | |

| Tel.: 030 - 3429075 | email: wischnewski@peacesoftware.de |

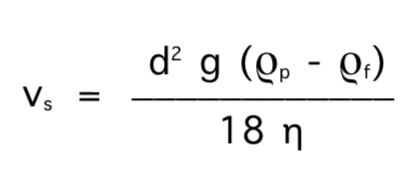

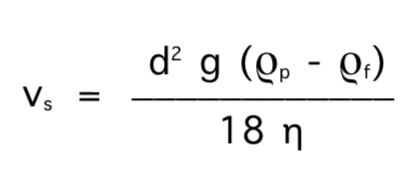

First of all, Stokes' equation is used to calculate the rate of descent, which is based on the following ideal conditions. The sediment particles are smooth spheres that settle in an infinitely extended liquid, in which neither the walls nor neighboring particles affect the settling speed.

| vs: | Rate of descent | [ m / s] |

| d: | Grain diameter | [ mm ] |

| g: | Acceleration due to gravity | [ 9,81 m / s2 ] |

| ρp: | Grain density | [ kg / m3 ] |

| ρf: | Density liquid | [ kg / m3 ] |

| η: | Dynamic viscosity liquid | [ Pa / s ] |

| ν: | Kinematic viscosity liquid | [ m2 / s ]  |

| Re: | Reynolds number | |

| CD: | Drag coefficient |

The conditions for the application of the Stokes formula are mostly not fulfilled in real sediments:

Grain structure of sand

Grain structure of sand

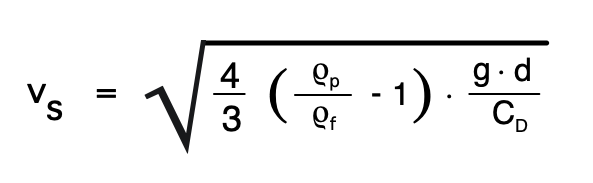

To correct the deviations caused by the turbulence, the following formula is calculated with the drag coefficient CD:

The drag coefficient CD depends on the Reynolds number.

For low sedimentation velocities or Reynolds numbers < 0.5, laminar flow, CD = 24 / Re applies. In this case, the sedimentation rate can be calculated using Stokes' equation.

If the Reynolds number is in the transition range between 0.5 < Re > 1000 there is no simple formula for CD, but various empirical formulas, e.g. B. CD = 18.5 / Re0.6 .

For high sedimentation velocities or Reynolds numbers Re > 1000, turbulent flow, CD = 0.44.

Sedimentationsgeschwindigkeit Wikipedia

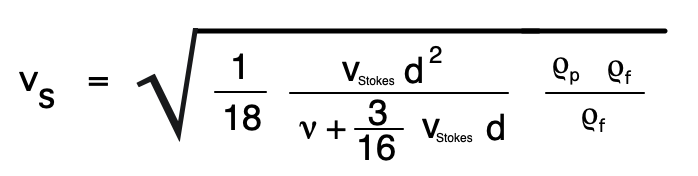

Oseen provides an improved approach to calculating sink rate.

For particle diameters of up to about 0.1 mm, the approaches according to Stokes and Oseen deliver almost the same sinking speeds. For larger grain diameters, the Stokes range of application ends and the Oseen equation gives better results.

| Group | Material | Grain size [ mm ] | |

| Gravel | Coarse gravel | 20 - 63 | |

| Medium Gravel | 6.3 - 20 | ||

| Fine gravel | 2 - 6.3 | ||

| Sand | Coarse sand | 0.63 - 2 | |

| Medium sand | 0.2 - 0.63 | ||

| Fine sand | 0.063 - 0.2 | ||

| Silt | Coarse silt | 0.02 - 0.063 | |

| Medium silt | 0.0063 - 0.02 | ||

| Fine silt | 0.002 - 0.0063 | ||

| Tone | Coarse tone | 0.00063 - 0.0.002 | |

| Midtone | 0.0002 - 0.00063 | ||

| Fine tone | < 0.0002 |

Grain size: [ mm ]

Material |

Density [kg / m3] | |

| Sand | 2650 | |

| Lignite, oil shale, hard coal | 1250 | |

| Metals / Alloys | ||

| Iron | 7874 | |

| Steel | 7840 | |

| Cast iron | 7200 | |

| Aluminium | 2700 | |

| Copper | 8960 | |

| Zinc | 7140 | |

| Zinn | 7300 | |

| Gold | 19320 | |

| Silver | 10460 | |

| Platinum | 21450 | |

| Lead | 11340 | |

| Brass | 8500 | |

| Bronze | 8730 | |

Density of material: [ kg / m3 ]

Density of fluid: [ kg / m3 ]

| 0 degree C | |

| 1 degree C | |

| 3 degree C | |

| 5 degree C | |

| 10 degree C | |

| 15 degree C | |

| 20 degree C | |

| 22 degree C | |

| 25 degree C | |

| 30 degree C | |

| 35 degree C | |

| 40 degree C | |

| 50 degree C | |

| 60 degree C | |

| 70 degree C | |

| 80 degree C | |

| 90 degree C | |

| 95 degree C | |

| 100 degree C |

Dynamic viscosity of the fluid: [ Pa /s ]